The final stage before animation was to apply texture, specular and bump maps to the objects. As a group we decided that a lot of the texturing will be done by all group members as this alleviated the work load and allowed us to focus on the animation and post production.

In preparation for the texturing phase, Tom and I downloaded a large collection of different textures that could be used for our project. I also created a brushed metal effect texture and manipulated another texture to my own requirements for use on the models I created. These were saved within the group work folders we share so other members of the group could use the same textures if needed.

As a lot of the steam pumps components featured a brushed metal effect so I thought it would be ideal to create one from scratch because its simple to create and I can make it as high a resolution as needed. I started with an image resolution of 1200 by 800 and filled the background grey. I applied a noise filter (14% gaussian, monochromatic), followed by a motion blur filter (angle 0, distance 41 pixels).

This is the final texture image used for the objects within 3ds Max.

Within 3ds Max I opened my model of a metallic cap and applied the brushed metal texture to each object via the diffuse map properties. Inside the diffuse map settings, under co ordinates I increased the U and V tiling to 3.0 each. .I dragged the diffuse map image down to the bump map properties to copy the image into the bump map settings. I then lowered the amount of bump down to 81.

I added specular highlights to the material inside the 'Blinn' parameter. Under the blinn properties I raised the specular level and glossiness to 74 and 27.

I found a texture online of a grainy, dirtied metal that suited the sort of material I needed for some of the steam pumps components. However upon applying the texture to the wheel object I found that the texture appeared more wooden than metal, even with specular mapping applied and tweaked. I imported the image into Photoshop and applied a few changes to make it appear more metallic. The image below is the standard texture, and the second image is the modified texture.

To start with I made the colour in the image much bolder by changing the hue and saturation with image adjustments properties.

I wanted to remove the black spots from the image as these were appearing more like dark spots on wood rather than a dirtied metallic effect. I used the patch tool within Photoshop to select the areas I wanted to remove and replaced them with the clearer sections of the image.

Finally I applied a motion blur texture like the brushed metal effect image. This gave me a much better image to work with.

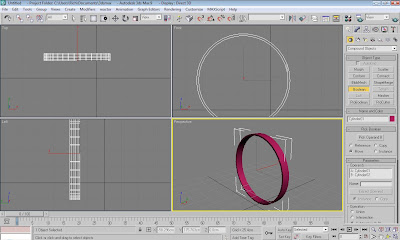

I opened the wheel model within 3ds Max and applied the texture to the diffuse and specular level map properties for all the objects in the scene apart from the outer rim which will be a steel texture. I decreased the specular level map amount to 85.

Under the basic shader properties I changed the 'Blinn' parameter to 'Anisotropic' which gave the wheel model texture a much more realistic metallic texture. I tweaked the anisotropic parameters by changing the specular colour to a light pink instead of bright white, specular highlights to 166, glossiness to 30 and the anisotropic to 65. Orientation was left at 0 as there was no need to change this after experimenting with different settings.

For the outer rim of the wheel I applied a steel texture to the diffuse map. I changed the diffuse map U and V tiling parameters to 2.5 by 1.3 because the objects surface is quite thin. Within the blinn shader parameters I set the specular level to 149 and the glossiness to 10.

The red metallic texture was also used on another main component. I modeled a mechanism which is used in the centre of the steam pump and is made of the same metallic material as most of the other parts, such as the wheel.

I imported four separate materials into the library, the red metallic texture, the brushed metal texture, a concrete texture and a dirtied metal texture, each with their bump map amounts set to around 80. Each material also had their basic shader parameters changed from blinn to anisotropic.

The individual settings were all slightly different, specular levels ranging from 79 to 111, glossiness 19 to 65, anisotropic 57 to 72 and orientation ranging from 10 to 116.

Below is a rendered sequence of three images from applying the material to bump then specular mapping.

Using reference photos for guidance I was able to accurately copy the types of textures on the object. Also as some objects had different types of materials on the same object I had to use the polygon sub selection tool to select individual polygons I wanted to apply a texture to.

Wednesday, 25 November 2009

Thursday, 12 November 2009

Mechanism

My next job for my group was to help model the moving mechanisms in the centre of the steam pump. At first this looked quite daunting and complicated, and the animation was going to be even more difficult by the look of it.

We decided to break up the work load between two members. My part was to model the triangle shaped mechanism and the other smaller parts that surround it. As this was an awkward shape to undertake I started to build it up slowly and worry about the finer details later on. At first I tried to create the basic shape by creating a square with a lot of segments that I could manipulate into the shape I wanted, however this was fairly inaccurate and didn't look very good.

I decided instead to use the line tool with properties of the line tool set to 'Smooth' so I could create a fluid line with no straight lines. This created a much more realistic and better looking shape.

I converted the line shape to an editable poly and extruded the shape out into the right width and height.

Like all line shape converted to an editable poly the reverse side border must be selected and 'capped' to create a polygon in the empty space.

As the shape had a hole through the middle I cloned the object and scaled it smaller and wider so I could boolean the object, creating a hole.

For the next part I created a cylinder that would be put on the right hand side where the triangle object comes to a point. I gave the cylinder 32 sides for a much more rounded and smooth edge. I then cloned the object, scaled it down and placed it inside the first cylinder.

I cloned the cylinder again and scaled it down significantly, increased the length and again placed it inside the second cylinder. However this time I booleaned the smallest cylinder creating a small hole in the centre, which is very similar to the actual design.

To create the metal poles that hold the main component and allow it to move from side to side, I created a cylinder that was about the right size and increased the amount of segments. Once converted to an editable poly I could select the end polygons via the sub selection mode and and scaled them so they were slightly larger, creating a shape that was similar to the real design.

the cylinder shape also had a small metal shape that points out and away from the object, so to create this I simply made a square, changed the shape to the right size, decreased all the segments as this object didn't need them and rotated it slightly.

I grouped the cylinder shape and the small metallic square and cloned them and copied them on the other side of the main component, reversing the little square.

Inside the cylinders I created another one, but much longer and more slim. These are the parts that allow the movement of the mechanism, and are attached to the main body of the pump . I created one for each side.

Now that I had the main shape and body of the component, I went back and started to add more detail. The top part of the main triangle shape has a raised edge that runs around it with one part having a rectangle hole. To create it I made a rectangle, then another smaller and slimmer rectangle in the centre which I would boolean to create the hole.

To blend the object in to the triangle shape, I rotated the rectangle slightly and made it fit, then turned the object into an editable poly, with the vertices at each corner selected I pulled them out so there was a slight angle rather than straight down which would create a more obvious contrast between the two objects.

I then needed to create the raised edge around the triangle. I used the line tool again and drew out the shape on one side .

and again on the other side.

I converted the line objects to editable polys and extruded the shapes to the right size, capped the reverse sides and moved them into the right place.

Within the raised edges there were also two circular objects that were there for attaching the small metal oil pots that I had modeled before. To create the circular base objects I made a cylinder and placed it in the right position, converted the object to a editable poly and with the top polygon selected I used the bevel tool to create a rounded tip.

I placed one either side and used the scale and move tool to make sure they were in the right position and didn't look out of place.

I imported my metal oil pot that I created before and placed two on top of the circular bases. I had to make slight adjustments to the oil pot with the scale tool to get a good fit. I also rotated them so they were facing the directions they were in the photographs.

The final part of the model to create was a thick rectangle shape that moves up an down in the middle of the main component while it moves side to side. This was a particularly difficult object to model correctly because of the shape and the position its situated in.

Like the first part, I decided to build it up in a very basic form then make it appear much more detailed later. I used a cylinder and with the scale tool made it wider, creating an egg shape. Then I made a rectangle that made up the main section. I made another rectangle, but smaller and thinner, I used the boolean tool to cut a hole in the main section.

Using the line tool again I created a shape which over lapped the cylinder shape slightly and ran halfway across the main section. Again I converted this line object to an editable poly, extruded and capped the reverse side.

The top section I created with the line tool also had a small rectangle hole with a raised edge. I created a rectangle with a couple of segments and converted it to an editable poly, then pulled out the verticies on one side and brought them up slightly creating a slope in the shape.

After using the boolean tool to cut the shape out, I created a small rectangle shape that sticks out from the object and gave it more segments, converted it to an editable poly and moved the points either side down a bit, making it look a bit like an arc. I then applied a mesh smooth modifier to make it appear smoother.

Along the top section again, there is another hole in the surface, a dark dent in the object further back from the first. This time I used a pyramid object and rotated it upside down, scaled it to the right side and placed it where the hole would be.

Using the boolean tool again I cut the pyramid out of the surface below. I also placed a small sphere in the centre to give it bit of detail that closely resembles the real surface.

The last bit of detail I added was a sphere on the side, it added some more depth to the object and made it look more like the real object.

I grouped all the objects together and changed the colours of the objects to help with texturing later on. Below is the final model of the object.

We decided to break up the work load between two members. My part was to model the triangle shaped mechanism and the other smaller parts that surround it. As this was an awkward shape to undertake I started to build it up slowly and worry about the finer details later on. At first I tried to create the basic shape by creating a square with a lot of segments that I could manipulate into the shape I wanted, however this was fairly inaccurate and didn't look very good.

I decided instead to use the line tool with properties of the line tool set to 'Smooth' so I could create a fluid line with no straight lines. This created a much more realistic and better looking shape.

I converted the line shape to an editable poly and extruded the shape out into the right width and height.

Like all line shape converted to an editable poly the reverse side border must be selected and 'capped' to create a polygon in the empty space.

As the shape had a hole through the middle I cloned the object and scaled it smaller and wider so I could boolean the object, creating a hole.

For the next part I created a cylinder that would be put on the right hand side where the triangle object comes to a point. I gave the cylinder 32 sides for a much more rounded and smooth edge. I then cloned the object, scaled it down and placed it inside the first cylinder.

I cloned the cylinder again and scaled it down significantly, increased the length and again placed it inside the second cylinder. However this time I booleaned the smallest cylinder creating a small hole in the centre, which is very similar to the actual design.

To create the metal poles that hold the main component and allow it to move from side to side, I created a cylinder that was about the right size and increased the amount of segments. Once converted to an editable poly I could select the end polygons via the sub selection mode and and scaled them so they were slightly larger, creating a shape that was similar to the real design.

the cylinder shape also had a small metal shape that points out and away from the object, so to create this I simply made a square, changed the shape to the right size, decreased all the segments as this object didn't need them and rotated it slightly.

I grouped the cylinder shape and the small metallic square and cloned them and copied them on the other side of the main component, reversing the little square.

Inside the cylinders I created another one, but much longer and more slim. These are the parts that allow the movement of the mechanism, and are attached to the main body of the pump . I created one for each side.

Now that I had the main shape and body of the component, I went back and started to add more detail. The top part of the main triangle shape has a raised edge that runs around it with one part having a rectangle hole. To create it I made a rectangle, then another smaller and slimmer rectangle in the centre which I would boolean to create the hole.

To blend the object in to the triangle shape, I rotated the rectangle slightly and made it fit, then turned the object into an editable poly, with the vertices at each corner selected I pulled them out so there was a slight angle rather than straight down which would create a more obvious contrast between the two objects.

I then needed to create the raised edge around the triangle. I used the line tool again and drew out the shape on one side .

and again on the other side.

I converted the line objects to editable polys and extruded the shapes to the right size, capped the reverse sides and moved them into the right place.

Within the raised edges there were also two circular objects that were there for attaching the small metal oil pots that I had modeled before. To create the circular base objects I made a cylinder and placed it in the right position, converted the object to a editable poly and with the top polygon selected I used the bevel tool to create a rounded tip.

I placed one either side and used the scale and move tool to make sure they were in the right position and didn't look out of place.

I imported my metal oil pot that I created before and placed two on top of the circular bases. I had to make slight adjustments to the oil pot with the scale tool to get a good fit. I also rotated them so they were facing the directions they were in the photographs.

The final part of the model to create was a thick rectangle shape that moves up an down in the middle of the main component while it moves side to side. This was a particularly difficult object to model correctly because of the shape and the position its situated in.

Like the first part, I decided to build it up in a very basic form then make it appear much more detailed later. I used a cylinder and with the scale tool made it wider, creating an egg shape. Then I made a rectangle that made up the main section. I made another rectangle, but smaller and thinner, I used the boolean tool to cut a hole in the main section.

Using the line tool again I created a shape which over lapped the cylinder shape slightly and ran halfway across the main section. Again I converted this line object to an editable poly, extruded and capped the reverse side.

The top section I created with the line tool also had a small rectangle hole with a raised edge. I created a rectangle with a couple of segments and converted it to an editable poly, then pulled out the verticies on one side and brought them up slightly creating a slope in the shape.

After using the boolean tool to cut the shape out, I created a small rectangle shape that sticks out from the object and gave it more segments, converted it to an editable poly and moved the points either side down a bit, making it look a bit like an arc. I then applied a mesh smooth modifier to make it appear smoother.

Along the top section again, there is another hole in the surface, a dark dent in the object further back from the first. This time I used a pyramid object and rotated it upside down, scaled it to the right side and placed it where the hole would be.

Using the boolean tool again I cut the pyramid out of the surface below. I also placed a small sphere in the centre to give it bit of detail that closely resembles the real surface.

The last bit of detail I added was a sphere on the side, it added some more depth to the object and made it look more like the real object.

I grouped all the objects together and changed the colours of the objects to help with texturing later on. Below is the final model of the object.

Tuesday, 10 November 2009

Oiling The Joints

My next part of the modeling process involved me creating a small metal pot/cap that is attached to multiple points on the steam pump. The metal pots, we believe, were used to allow oil to be applied to the core parts inside the engine.

I started by creating the small screw nut that attaches the metal pot to the pump. This was simply created with a cylinder with the sides decreased to 8, smoothing off and with a radius of 3cm.

The next stage was the main body. This again was a cylinder, but a bit bigger with the smoothing on. To create the lid I converted the object to an editable poly to allow me to manipulate individual polygons and points. I selected the polygons on the top of the cylinder and using the bevel tool I extruded and scaled the polygons larger then back in again, creating the effect of a lid on the cylinder.

On the side , at the top of the cap, there is a small lip which would be were you would flick open the lid. I created this part by selecting the polygons on a side and pulling them out creating the lip. With a mesh smooth modifier applied this section now looked similar to the actual part.

A hinge would have to be applied to the back of the metal cap. This was made by using a square shaped rectangle object at 4cm high with 3 width and height segments. Then converting it to an editable poly I could select the polygons down one side and pull them in from the bottom up, creating an incline from top to bottom. I then applied a mesh smooth modifier to make it look more realistic and less like a box.

For extra detail on the hinge I created to small spheres to go either side to look like small bolts holding the hinge.

A final added touch to the top of the metal cap included a small cylinder which acts as a kind of cover between the hinger and the lid. This was just a small cylinder with a mesh smooth applied.

Below is the final model for the metal cap. Like the wheel, this model has all objects grouped and named appropriately for easy import and export. This model can easily be cloned multiple times as needed for the final steam pump model.

I started by creating the small screw nut that attaches the metal pot to the pump. This was simply created with a cylinder with the sides decreased to 8, smoothing off and with a radius of 3cm.

The next stage was the main body. This again was a cylinder, but a bit bigger with the smoothing on. To create the lid I converted the object to an editable poly to allow me to manipulate individual polygons and points. I selected the polygons on the top of the cylinder and using the bevel tool I extruded and scaled the polygons larger then back in again, creating the effect of a lid on the cylinder.

On the side , at the top of the cap, there is a small lip which would be were you would flick open the lid. I created this part by selecting the polygons on a side and pulling them out creating the lip. With a mesh smooth modifier applied this section now looked similar to the actual part.

A hinge would have to be applied to the back of the metal cap. This was made by using a square shaped rectangle object at 4cm high with 3 width and height segments. Then converting it to an editable poly I could select the polygons down one side and pull them in from the bottom up, creating an incline from top to bottom. I then applied a mesh smooth modifier to make it look more realistic and less like a box.

For extra detail on the hinge I created to small spheres to go either side to look like small bolts holding the hinge.

A final added touch to the top of the metal cap included a small cylinder which acts as a kind of cover between the hinger and the lid. This was just a small cylinder with a mesh smooth applied.

Below is the final model for the metal cap. Like the wheel, this model has all objects grouped and named appropriately for easy import and export. This model can easily be cloned multiple times as needed for the final steam pump model.

Monday, 9 November 2009

The Wheel

Before starting the modeling process, as a group we decided it would be best to set up the correct measurements. This is so we can be sure whatever we model will be at the correct scale and when it comes to importing all objects to one file the objects are not hugely off scale. Within 3ds Max, under 'Customize' and 'Units Setup', there is an option to change the default unit scale to Metric and then Centimetres. Inside the 'System Units Setup' there is another option to change from Metres to Centimetres.

With the units set up ready for creating objects I began creating the wheel. I created a cylinder about 9cm thick with a radius of 70cm, which I thought would be a rough estimate of the object. Getting the exact measurements isn't required as of yet because everything can be scaled slightly before the mapping stage. I increased the sides to 18 and checked the 'smooth' box to get a much more rounded look.

To create the hole in the centre of the wheel I had to clone the wheel, lower the radius and increase the height so it could be positioned in the centre and then use the boolean tool.

I created another cylinder like the first but with a slightly smaller height and radius. I repeated the same process as above and booleaned a hole in the middle of the cylinder, however this time made the hole smaller.

This created a much more realistic looking wheel.

The next stage was to create the centre of the wheel. Using a chamfer cylinder I created a rounded off cylinder shape with 14 sides. A mesh smooth modifier made a good shape which matched the the real wheel.

In the research photos I found that the centre of the chamfered cylinder the shape grew slightly larger. I converted the shape into an editable poly and with lines sub selection I scaled the centre to make it slightly larger.

I made another chamfer cylinder and made it much smaller, this would appear in the centre of the first chamfered cylinder object. This object wouldn't need a mesh smooth.

To finish off the centre I needed to make an object that sort of wrapped around the centre chamfer cylinder. This would be where the wheels spokes would attach from. I made a standard cylinder object with 14 sides that would be larger than the chamfer cylinder and applied a mesh smooth.

The final stage of the wheel would be creating the spokes that fill the middle. I started by just creating a single rectangle to get the rough size and shape of a single spoke. Converting the rectangle object to an editable poly allowed me to change the points at either end of the rectangle to make the object look as if it was moulded to the wheel frame and the wheel centre.

I applied a mesh smooth to the object which gave the rectangle a more realistic look for the metal poles that make the wheels spokes. Cloning and rotating the objects gave me the desired look for the wheel.

Below is the finished model with no textures applied.

With the units set up ready for creating objects I began creating the wheel. I created a cylinder about 9cm thick with a radius of 70cm, which I thought would be a rough estimate of the object. Getting the exact measurements isn't required as of yet because everything can be scaled slightly before the mapping stage. I increased the sides to 18 and checked the 'smooth' box to get a much more rounded look.

To create the hole in the centre of the wheel I had to clone the wheel, lower the radius and increase the height so it could be positioned in the centre and then use the boolean tool.

I created another cylinder like the first but with a slightly smaller height and radius. I repeated the same process as above and booleaned a hole in the middle of the cylinder, however this time made the hole smaller.

This created a much more realistic looking wheel.

The next stage was to create the centre of the wheel. Using a chamfer cylinder I created a rounded off cylinder shape with 14 sides. A mesh smooth modifier made a good shape which matched the the real wheel.

In the research photos I found that the centre of the chamfered cylinder the shape grew slightly larger. I converted the shape into an editable poly and with lines sub selection I scaled the centre to make it slightly larger.

I made another chamfer cylinder and made it much smaller, this would appear in the centre of the first chamfered cylinder object. This object wouldn't need a mesh smooth.

To finish off the centre I needed to make an object that sort of wrapped around the centre chamfer cylinder. This would be where the wheels spokes would attach from. I made a standard cylinder object with 14 sides that would be larger than the chamfer cylinder and applied a mesh smooth.

The final stage of the wheel would be creating the spokes that fill the middle. I started by just creating a single rectangle to get the rough size and shape of a single spoke. Converting the rectangle object to an editable poly allowed me to change the points at either end of the rectangle to make the object look as if it was moulded to the wheel frame and the wheel centre.

I applied a mesh smooth to the object which gave the rectangle a more realistic look for the metal poles that make the wheels spokes. Cloning and rotating the objects gave me the desired look for the wheel.

Before saving the object I named each part of the wheel so later on in the project there would be less confusion when everything is combined. I also grouped all the objects together to allow for easy rotation and animation later on.

Below is the finished model with no textures applied.

Subscribe to:

Comments (Atom)